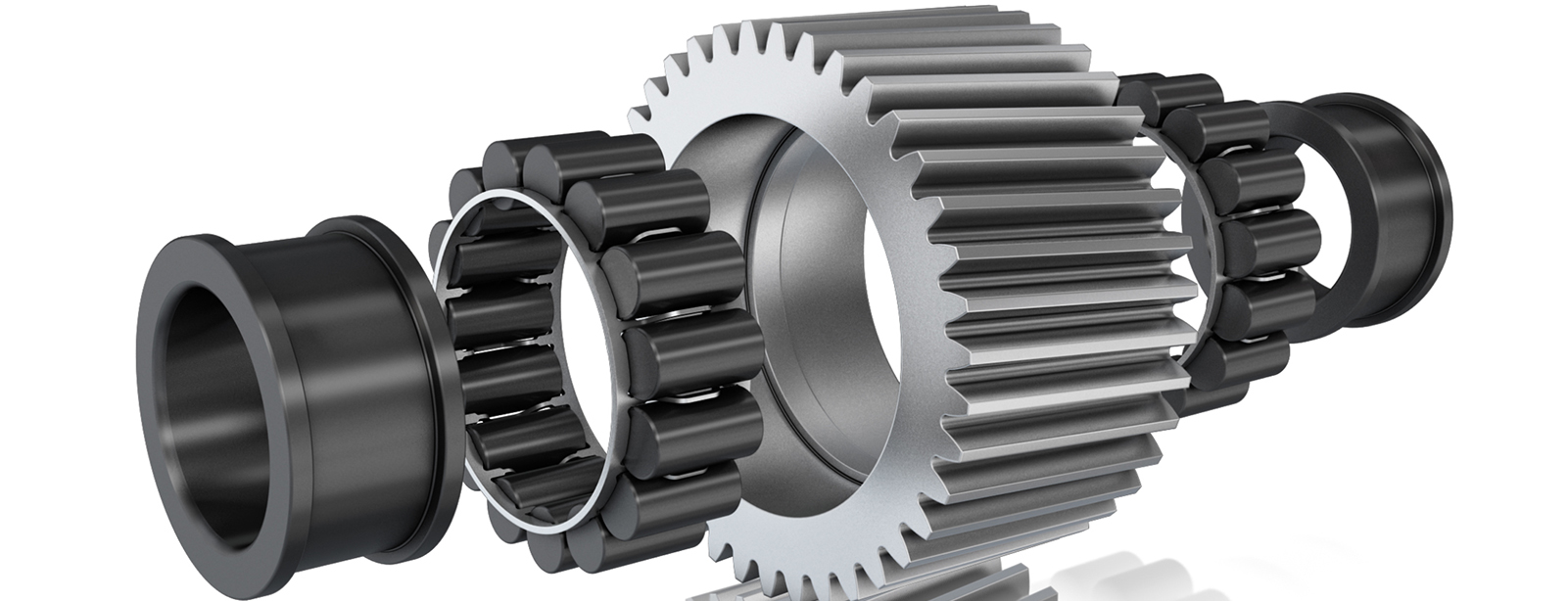

- Machine tool for High speed precision Machining (High-speed Inline Center)

- Precision Spindle Support

- NACHI High-speed Inline Center

- These bearings are designed with three contact angle classifications as shown in Table 1.

- Normally, contact angle A design and B design are fitted with a cage as shown in Table 2.

- High precision (JIS/ISO class 5 or higher) may be fitted with a machined cage of bronze or phenolic resin or a polyamide cage.

Contact angle C design are generally applied high precision, JIS (ISO) class 5 or higher, and are fitted with a machined phenolic resin cage or a polyamide cage.

Contact Angle and Characterisics of Single-row Angular Contact Ball Bearings

Contact

Angle

Symbol |

Example

Bearing

No. |

Contact

Angle

(α) |

Speed |

Load capability (*2) |

Cross Section |

| Radial Load Direction(X) |

Axial Load

Direction (Y) |

| A |

7205(*1) |

30° |

Normal |

Normal |

Normal |

|

| B |

7205B |

40° |

Low |

Low |

High |

| C |

7205C |

15° |

High |

High |

Low |

(Note)

*1: Contact angle symbol "A" is omitted.

*2: Axial load be accommodated in one direction only.

Standard Cage Materials (For JIS / ISO class 0 or 6)

| |

Applicable Bore Diameter Number |

| Pressed Steel |

Machined Brass |

| 72, 72B |

00 - 22 |

24 - 40 |

| 73, 73B |

00 - 19 |

20 - 40 |

- Machine tool for High speed precision Machining (High-speed Inline Center)

- Machine tool for High speed precision Machining (High-speed Inline Center)